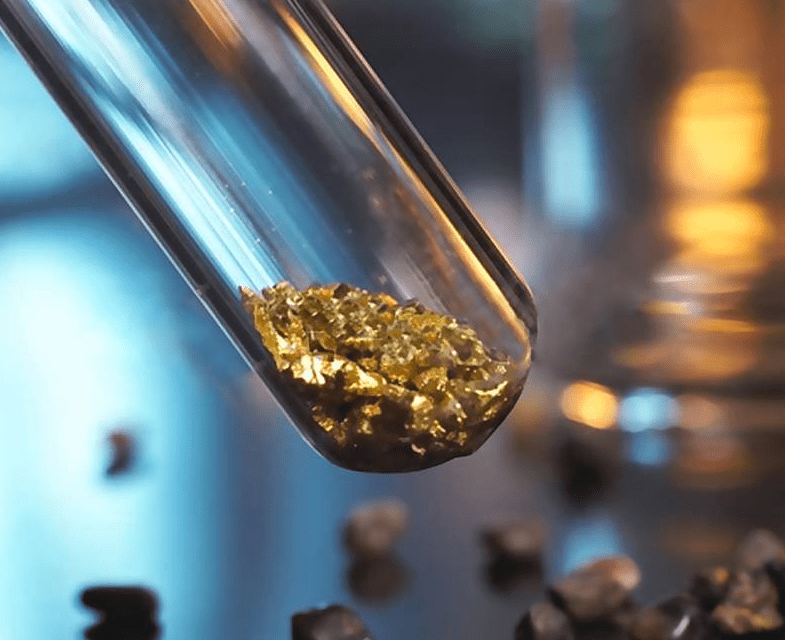

Gold, the most loved metal in the world, does not exist in its purest form naturally. The metal is mined and is extracted from its ores. The gold obtained after the mining process is impure. It is a mixture of many impurities that need to be removed before being available for consumption in the bullion ecosystem. This is done through gold refinement process.

Among the various techniques and methodologies used for the refinement of gold, Royal Ghana Gold Ltd, brings a world-class refinery, equipped with the latest technological innovations there are. With a refining capacity of 400-kg per day, we celebrate Accuracy, Purity, and Skill. We specialize in refining and evaluation of large volumes of precious metals, with a commitment to deliver the highest quality and highest refining capacity in the Ghana region.

An important process during the metal extraction, Royal Ghana Gold Limited specializes in smelting of Gold through Electric Induction Furnace. Gold is purified by means of a smelting process, which utilizes pressure, high heat and chemicals to accomplish the task. Like any metal that appears naturally in the earth, there are impurities that must be removed. Removing minerals and other impurities allows gold to be used in its purest form. We assure our clients of highest degree of quality and accuracy. We use a combination of different equipment and sophisticated methods to pre-refine our metal, to achieve highest degree of quality and accuracy.

amount of pure gold in a mineral deposit. The process involves bringing a rock sample, most often a core obtained through drilling, to a laboratory where it is examined by experts. Assay results are often mapped and used to pinpoint targets for future drill programs.

us the knowledge, skills, experience as well as tools to confirm gold content in the metal scrap in a standardized assay process. Royal Ghana Gold Ltd takes pride in a full-service Assay lab fitted with Thermo Fischer equipment. Our Assay lab offers a comprehensive set of services that include fire, XRF, spectrometrics, ICP, X-ray and chemical assays. All sourced raw material is melted and sampled for purity assessment.

because it guarantees consistently accurate data on every refining batch. We are constantly striving to perfect the centuries-old tradition of assaying by using the most advanced technologies to achieve the highest standard of excellence and endeavor.

designers has all the necessary skills and equipment to offer our clients a bespoke range of options associated with gold and silver minting. Very soon, Royal Ghana Gold clients will be able to custom-order and choose from available range of cast bars, ingots and coins.

and minted at our fully integrated refining facility, ensuring they meet the stringent standards for purity set by LBMA. Our clients can customize their orders to their preferences and expect a finished product of superior quality.

Ghana Gold Ltd. provides 100% gold buyback services at competitive rates for scrap gold jewellery, bars, coins and ingots. The accuracy of gold content is determined through a certified professional assaying and valuation process.

metals transparent & trouble-free and assure you with the certainty of a professional valuation and a fair price for your precious metals.